Tel : +86-18850221490

Email : info@utextester.com

ASTM D5035 provide a test method to measure the maximum breaking force and elongation for most textile fabrics under raveled strip and cut strip mehtods. The raveled strip test is applicable to woven fabrics while the cut strip test is applicable to nonwoven fabrics, felted fabrics, and dipped or coated fabrics. However, This test method is not recommended for knitted fabrics or for other textile fabrics which have high stretch (more than 11%).

Principle

The strength tester clamps the sample and applies the load until the sample is broken, and read the breaking strength and breaking elongation.

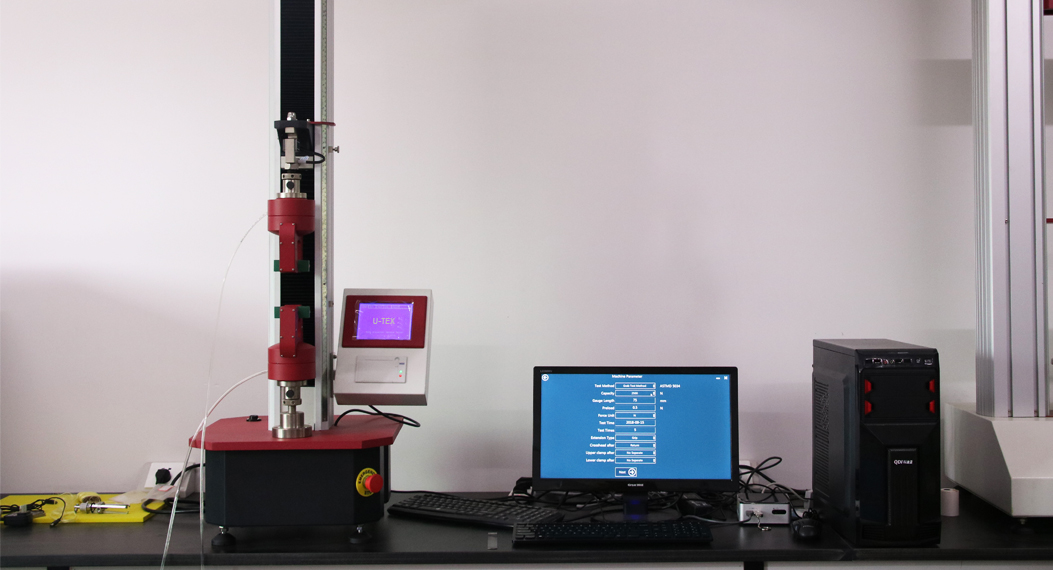

Materials Testing System

There is an important point need to consider it is about the data collection frequency for a testing machine. In order to measure the tear strength of the material consistently and accurately, it is important to remember that the data sampling rate needs to be high enough to adequately capture the test peaks and valleys. U-TEX UT002A is recommended to use which occupies the collection frequency with 2000 times/sec. For most textile fabric testing according to ASTM D5035, single column frame with 2.5KN load cell is enough for regular tests.

Grips

The samples tested in accordance with ASTM D5035 are paired with sufficient clamps using jaw faces that have a minimum width of at least 10 mm wider than the width of the sample and a minimum height of 25 mm. Although manual clamps are acceptable, pneumatic lateral clamps are recommended because of their ease of use, high repeatability and high throughput. The adjustable clamping pressure also allows the user to fine-tune the clamping pressure to avoid jaw breaks or slippage.

ASTM D5035 requires the use of a smooth and flat jaw surface for testing, but this mainly depends on the material being tested. A rubber-coated jaw surface is usually the first choice. In some cases, where the fabric sample is strong or slippery, a serrated jaw surface may be more suitable. The standard also requires the ability to use additional filler materials (such as paper or emery cloth) in the jaw surfaces as an additional method to help prevent slippage.

Notes

The standard recommends the use of a constant elongation (CRE) frame for testing, however, it also states that a constant load rate or constant traverse rate is also acceptable. When using different testing machines to test the same material, it is recommended to use a constant breaking time of 20 ± 3 seconds to obtain the most comparable results. It should be noted that depending on the framework used, the results may still vary greatly.

ASTM D5035 requires the preparation of two sets of samples, one in the warp direction and the other in the weft direction.

The U-TEX UT002A test software has advanced pre-built test methods and pre-configured calculation formula to help ensure compliance with ASTM D5035.